A260Ni Aluminium Alloy Manufacturer

Precision Alloy is a specialized manufacturer and exporter of A260Ni Aluminum Alloy, a high-strength, nickel-modified aluminum alloy designed for critical aerospace, defense, and precision-engineered applications requiring excellent fatigue resistance, thermal performance, and dimensional stability.

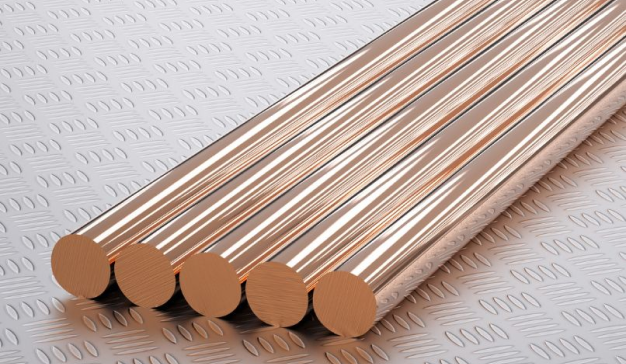

We offer A260Ni alloy in rods, bars, forged blanks, machined parts, and custom-formed components, ideal for components exposed to high mechanical load and cyclic thermal stress.

What is A260Ni Aluminium Alloy?

A260Ni is a high-performance aluminum alloy that contains significant levels of copper and nickel, offering superior fatigue strength, wear resistance, and creep resistance at elevated temperatures. This alloy is ideal for structural parts in aerospace assemblies, precision-machined parts, and load-bearing forged components that demand long-term stability.

Its nickel enrichment improves its performance in high-load, high-frequency environments such as jet engines, automotive performance parts, and industrial dies.

A260Ni Aluminium Alloy Specifications

| Property | Specification |

|---|---|

| Alloy Designation | A220Ni |

| Temper Available | F, T6, T651 |

| Product Forms | Bars, Rods, Plates, Forgings, Machined Parts |

| Size Range | Rods: 12 mm – 300 mm |

| Standards | In-house & customer-specific specs (similar to EN/ASTM/Aircraft Standards) |

A260Ni Aluminium Alloy Chemical Composition

| Element | % Composition |

|---|---|

| Aluminum (Al) | Balance |

| Copper (Cu) | 4.0 – 4.5 |

| Nickel (Ni) | 2.0 – 3.0 |

| Iron (Fe) | 0.50 max |

| Silicon (Si) | 0.20 – 0.40 |

| Manganese (Mn) | 0.30 – 0.80 |

| Zinc (Zn) | 0.25 max |

Mechanical Properties of A260Ni Aluminium Alloy

| Property | Typical Values |

|---|---|

| Tensile Strength | 490 – 540 MPa |

| Yield Strength | 360 – 420 MPa |

| Elongation | 8 – 12% |

| Hardness | 135 – 150 HB |

| Fatigue Strength | Superior |

| Thermal Resistance | Excellent |

| Machinability | High |

Applications of A260Ni Aluminium Alloy

A260Ni Aluminium Alloy are widely used due to their versatility, corrosion resistance, and clean finish:

Construction & Infrastructure

Automotive & Transportation

Marine & Offshore

Aerospace & Defence

Oil & Gas Industry

Manufacturing & Industrial Machinery

Why Choose Precision Alloy?

- ISO 9001:2015 Certified Manufacturer

- Wide Range of Stainless Steel Bar Shapes & Sizes in Stock

- Surface Finish Options for Decorative or Industrial Use

- Customized Machining & Fast Lead Times

- Global Delivery with Competitive Pricing

People Also Search For

🔹 High Strength Aluminium Bronze Rods

🔹 Aluminium Bronze C95400 vs C95500 Comparison

🔹 Corrosion-Resistant Aluminium Bronze Sheets

🔹 Aluminium Bronze Marine-Grade Alloys Supplier

🔹 Aluminium Bronze Valve Components Manufacturer

🔹 Heat-Treated Aluminium Bronze Bars for Bearings