Stainless Steel Bars

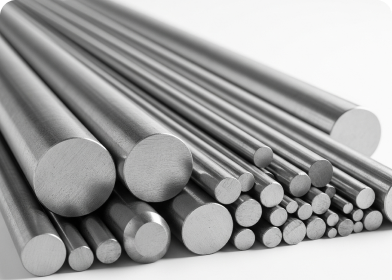

At Precision Alloys, we are at the forefront of manufacturing and supplying high-quality stainless steel bars, known for their precision, durability, and compliance with international standards. Our products cater to a wide range of industrial applications, and we provide customisable options in sizes, grades, and finishes to meet your specific requirements.

What are Stainless Steel Bars?

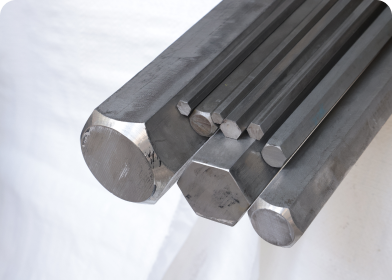

Stainless steel bars are robust, long-lasting metal sections available in various shapes including round, square, hexagonal, and flat. These bars are crucial in numerous sectors due to their high strength, notable corrosion resistance, and excellent formability. They are manufactured using several processes to achieve precise dimensions and desired mechanical properties.

Stainless Steel Bars Specifications

| Property | Specification |

|---|---|

| Material Grades | SS 304, SS 316, SS 321, SS 410, SS 430, 316ti , 347, 17-4 ph |

| Shapes Available | Round, Square, Hexagonal, Flat |

| Diameter Range | 5mm – 500mm |

| Length | Up to 6 meters (Custom sizes available) |

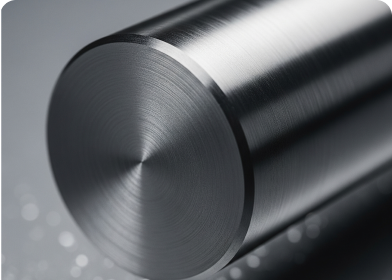

| Surface Finish | Bright, Black, Polished, Rough Turned |

| Manufacturing Process | Hot Rolled, Cold Drawn, Forged |

| Standards & Compliance | ASTM A276, ASME SA479, EN 10088, DIN 1.4301 |

Stainless Steel Bars Equivalent Grades

Stainless Steel Bars Equivalent Grades

| Grade | UNS | EN / WNR |

|---|---|---|

| SS 304 | S30400 | 1.4301 / X5CrNi18-10 |

| SS 316 | S31600 | 1.4401 / X5CrNiMo17-12-2 |

| SS 321 | S32100 | 1.4541 / X6CrNiTi18-10 |

| SS 410 | S41000 | 1.4006 / X12Cr13 |

| SS 430 | S43000 | 1.4016 / X6Cr17 |

Chemical Composition

| Element | SS 304 (%) | SS 316 (%) | SS 321 (%) |

|---|---|---|---|

| Carbon (C) | 0.08 max | 0.08 max | 0.08 max |

| Manganese (Mn) | 2.00 max | 2.00 max | 2.00 max |

| Silicon (Si) | 1.00 max | 1.00 max | 1.00 max |

| Chromium (Cr) | 18.0 – 20.0 | 16.0 – 18.0 | 17.0 – 19.0 |

| Nickel (Ni) | 8.0 – 10.5 | 10.0 – 14.0 | 9.0 – 12.0 |

| Molybdenum (Mo) | — | 2.00 – 3.00 | — |

Mechanical Properties of Stainless Steel Bars

| Grade | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (%) | Hardness (HRB / HRC) |

|---|---|---|---|---|

| SS 304 | 515 – 750 | ≥ 205 | ≥ 40 | ≤ 90 HRB |

| SS 304L | 485 – 700 | ≥ 170 | ≥ 40 | ≤ 90 HRB |

| SS 316 | 515 – 760 | ≥ 205 | ≥ 40 | ≤ 95 HRB |

| SS 316L | 485 – 700 | ≥ 170 | ≥ 40 | ≤ 95 HRB |

| SS 321 | 515 – 750 | ≥ 205 | ≥ 40 | ≤ 95 HRB |

| SS 347 | 515 – 750 | ≥ 205 | ≥ 40 | ≤ 95 HRB |

| SS 410 | 450 – 750 | ≥ 275 | ≥ 20 | 20–30 HRC |

| SS 420 | 700 – 900 | ≥ 345 | ≥ 15 | 48–52 HRC |

| SS 431 | 750 – 1050 | ≥ 500 | ≥ 15 | 30–40 HRC |

| 17-4PH | 930 – 1310 | ≥ 725 (Condition H900) | ≥ 10 – 17 | 35–44 HRC (depending on condition) |

| 2205 Duplex | 620 – 880 | ≥ 450 | ≥ 25 | ≤ 100 HRB |

| 2507 Super Duplex | 795 – 930 | ≥ 550 | ≥ 25 | ≤ 32 HRC |

Applications of Stainless Steel Bars

Our stainless steel bars find their application across a broad spectrum of industries due to their robustness and adaptability:

Construction & Infrastructure

Automotive & Transportation

Marine & Offshore

Aerospace & Defence

Oil & Gas Industry

Manufacturing & Industrial Machinery

Why Choose Precision Alloy?

- ISO 9001:2015 Certified Manufacturer

- Wide Range of Stainless Steel Bar Shapes & Sizes in Stock

- Surface Finish Options for Decorative or Industrial Use

- Customized Machining & Fast Lead Times

- Global Delivery with Competitive Pricing

People Also Search For

- Stainless Steel Bars Manufacturer in India.

- Buy High-Quality SS 316 Bars for Severe Conditions.

- Precision Ground Stainless Steel Bars Supplier.

- Durable Stainless Steel Bars for Heavy-Duty Applications.

- Customisable Stainless Steel Bars at Competitive Prices.

- Explore Duplex Stainless Steel Bars for Specialised Uses.