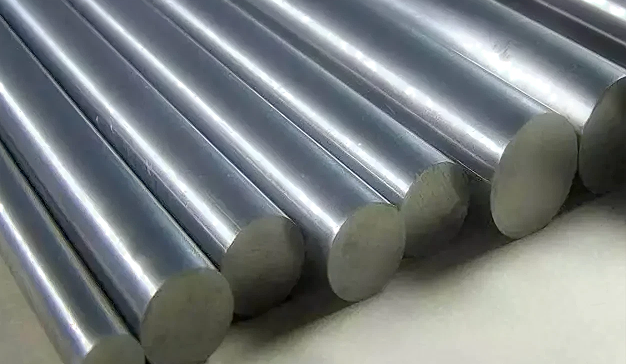

SS 347 Round Bar Manufacturer

SS 347 Round Bar is a stabilized austenitic stainless steel round bar that contains niobium (columbium) for enhanced resistance to intergranular corrosion. It is especially suitable for high-temperature service where carbide precipitation might otherwise occur in unstabilized grades like SS 304. With excellent creep strength and stress rupture properties, SS 347 round bars are commonly used in aerospace, refinery, chemical, and heat exchanger applications.

What is SS 347 Round Bar?

SS 347 is a titanium-free stainless steel stabilized with niobium to resist sensitization during welding and prolonged exposure to elevated temperatures. Unlike SS 321 which uses titanium as a stabilizer, SS 347 uses niobium (Nb) which forms niobium carbides, preventing the formation of chromium carbides and thereby protecting the metal from intergranular attack.

SS 347 round bars maintain their strength and corrosion resistance even in oxidizing environments and are ideal for high-stress components in high-temperature and corrosive applications.

Specifications – SS 347 Round Bars

| Parameter | Specification |

|---|---|

| Product Name | SS 347 Round Bar |

| Diameter Range | 6 mm to 350 mm |

| Length | 1000 mm to 6000 mm (Custom on request) |

| Finish Available | Bright, Black, Peeled, Polished |

| Condition | Annealed / Hardened / Tempered |

| Manufacturing Method | Hot Rolled / Cold Drawn / Forged |

| Tolerance | h9 / h10 / h11 (As per requirement) |

| Material Grade | AISI 347 / ASTM A276 / A479 |

| Certification | EN 10204 3.1 / 3.2, NACE MR0175, IBR, PED, ISO |

Chemical Composition – SS 347 Round Bars

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 9.0 – 13.0 |

| Niobium (Nb + Ta) | ≥ 10x C (min 0.3%) |

| Iron (Fe) | Balance |

Mechanical Properties – SS 347 Round Bars

| Property | Value |

|---|---|

| Tensile Strength | 515 – 750 MPa |

| Yield Strength (0.2%) | ≥ 205 MPa |

| Elongation (50mm) | ≥ 40% |

| Modulus of Elasticity | ~193 GPa |

| Hardness | ≤ 217 HB |

| Impact Toughness | Excellent at cryogenic temps |

| Melting Point | ~1398°C – 1446°C |

Applications of SS 347 Round Bars

Due to its excellent resistance to sensitization and high-temperature strength, SS 347 round bars are widely used in:

Construction & Infrastructure

Automotive & Transportation

Marine & Offshore

Aerospace & Defence

Oil & Gas Industry

Manufacturing & Industrial Machinery

Why Choose Precision Alloy?

- ISO 9001:2015 Certified Manufacturer

- Wide Range of Stainless Steel Bar Shapes & Sizes in Stock

- Surface Finish Options for Decorative or Industrial Use

- Customized Machining & Fast Lead Times

- Global Delivery with Competitive Pricing