Copper Alloys

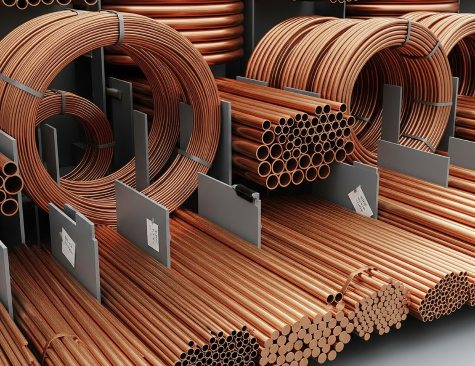

At Precision Alloy Co., we provide a diverse range of copper alloys, known for their superior thermal and electrical conductivity, corrosion resistance, and mechanical strength. Our copper alloys are tailored to support a variety of industrial applications, including electrical components, automotive parts, and architectural projects. Customise your order with our selection of grades and forms to meet the exact needs of your project.

What are Copper Alloys?

Copper alloys are metal alloys that have copper as their principal component, often alloyed with elements such as tin, zinc, nickel, and aluminium to enhance specific properties. These alloys are chosen for their excellent conductivity, malleability, and resistance to atmospheric and chemical corrosion, making them suitable for a wide range of applications.

Detailed Specifications of Copper Alloys

| Property | Specification |

|---|---|

| Alloy Groups | Bronze, Brass, Cupronickel, Nickel Silver |

| Forms Available | Sheets, Plates, Tubes, Bars, Wires, Strips |

| Composition | Varies by alloy (e.g., Cu-Sn, Cu-Zn, Cu-Ni) |

| Standards & Compliance | ASTM, SAE, EN, ISO 9001 |

Copper Alloys Equivalent Grades

Copper Alloys Equivalent Grades

- Bronze (e.g., C51000, C93200):

Known for its strength and corrosion resistance, commonly used in bearings and bushings. - Brass (e.g., C36000, C37700):

Excellent machinability and acoustic properties, used in musical instruments and hardware. - Cupronickel (e.g., C70600, C71500):

High resistance to corrosion in seawater, making it ideal for marine hardware and heat exchangers. - Nickel Silver (e.g., C75700, C79200):

Aesthetic appeal combined with strength, used in decorative applications and coins.

Applications of Copper Alloys

Copper alloys are integral to a broad spectrum of applications:

Construction & Infrastructure

Automotive & Transportation

Marine & Offshore

Aerospace & Defence

Oil & Gas Industry

Manufacturing & Industrial Machinery

Why Choose Precision Alloy?

- ISO 9001:2015 Certified Manufacturer

- Wide Range of Stainless Steel Bar Shapes & Sizes in Stock

- Surface Finish Options for Decorative or Industrial Use

- Customized Machining & Fast Lead Times

- Global Delivery with Competitive Pricing

People Also Search For

- High Conductivity Copper Alloys for Electrical Use

- Copper Alloy Rods vs Brass – Key Differences

- Corrosion-Resistant Copper Alloys for Marine Applications

- Copper Nickel Alloys for Heat Exchangers

- Lead-Free Copper Alloys for Plumbing Systems

- Beryllium Copper vs Phosphor Bronze – Which to Choose?