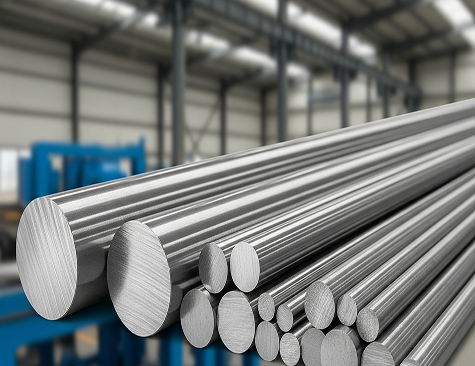

303 Stainless Steel Bars Manufacturer

What are 303 Stainless Steel Bars?

303 stainless steel bars are austenitic stainless steel bars specially formulated with added sulfur to improve machinability. While it offers slightly reduced corrosion resistance compared to SS 304, SS 303 is widely used for precision machining applications, especially in automotive, aerospace, electronics, and industrial equipment.

303 Stainless Steel Bars Specifications

| Property | Specification |

|---|---|

| Material Grade | SS 303 |

| UNS Number | S30300 |

| EN / WNR | 1.4305 / X8CrNiS18-9 |

| Shapes Available | Round, Square, Hexagonal, Flat |

| Size Range | 5mm – 200mm |

| Length | Up to 6 meters (Custom lengths available) |

| Surface Finish | Bright, Peeled, Ground, Polished |

| Manufacturing Process | Cold Drawn, Centerless Ground, Precision Machined |

| Tensile Strength | 500 – 750 MPa |

| Yield Strength | 190 – 300 MPa |

| Hardness | 85 – 95 HRB |

| Standards | ASTM A582, ASME SA479, EN 10088 |

Types of 303 Stainless Steel Bars

303 Stainless Steel Bar Chemical Composition

| Element | % Composition |

|---|---|

| Carbon (C) | 0.10 max |

| Manganese (Mn) | 2.00 max |

| Silicon (Si) | 1.00 max |

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 8.0 – 10.0 |

| Sulfur (S) | 0.15 – 0.35 |

| Phosphorus (P) | 0.20 max |

Mechanical Properties of 303 Stainless Steel Bars

| Property | Value |

|---|---|

| Tensile Strength | 500 – 750 MPa |

| Yield Strength | 190 – 300 MPa |

| Elongation | 35% (min) |

| Hardness | 85 – 95 HRB |

Applications of 303 Stainless Steel Bars

SS 303 bars are the go-to choice for high-speed machining, making them ideal for:

Construction & Infrastructure

Automotive & Transportation

Marine & Offshore

Aerospace & Defence

Oil & Gas Industry

Manufacturing & Industrial Machinery

Why Choose Precision Alloy?

- ISO 9001:2015 Certified Manufacturer

- Wide Range of Stainless Steel Bar Shapes & Sizes in Stock

- Surface Finish Options for Decorative or Industrial Use

- Customized Machining & Fast Lead Times

- Global Delivery with Competitive Pricing

People Also Search For

🔹 SS 303 Round Bar for CNC Machining

🔹 Best Machinable Stainless Steel Bars – SS 303 vs SS 304

🔹 ASTM A582 SS 303 Bright Bars Supplier

🔹 Buy SS 303 Hex Bars for Fasteners

🔹 SS 303 Flat Bars for Automation & Tooling

🔹 SS 303 vs SS 416 – Which Grade is Better for Machining?

Frequently Asked Questions

What makes SS 303 more machinable than SS 304?

SS 303 contains higher sulfur content, which improves chip formation and tool life during machining.

Can SS 303 be used in corrosive environments?

SS 303 offers good corrosion resistance, but for highly corrosive or marine environments, SS 316 is preferred.

Is SS 303 magnetic?

No, SS 303 is generally non-magnetic in the annealed condition but may become slightly magnetic after cold working.

Do you provide ground or turned SS 303 bars?

Yes, we supply centerless ground, peeled, and polished bars for high-precision applications.

What is the delivery time for custom 303 bar sizes?

Standard sizes ship within 3–5 days. Custom sizes and finishes typically take 7–10 working days.