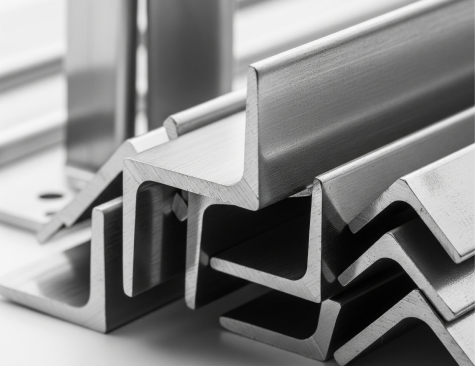

What are SS 347 Stainless Steel Angles?

What are SS 347 Stainless Steel Angles?

SS 347 stainless steel angles are titanium-stabilized austenitic stainless profiles that offer excellent resistance to intergranular corrosion and weld decay, especially during prolonged exposure to elevated temperatures or post-weld heat. The titanium content inhibits carbide precipitation, making SS 347 ideal for welded structures operating in cyclical thermal environments.

SS 347 Stainless Steel Angles Specifications

| Property | Specification |

|---|---|

| Material Grade | SS 347 |

| UNS Number | S34700 |

| EN / WNR | 1.4550 / X6CrNiNb18-10 |

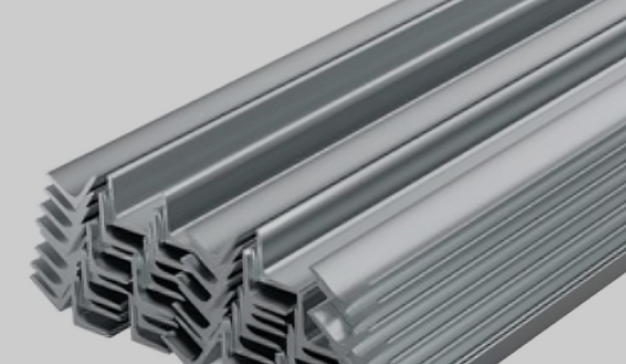

| Sizes | 20×20 mm to 150×150 mm (Equal & Unequal Angles) |

| Thickness | 3 mm – 12 mm |

| Length | 3m, 6m, or custom cuts |

| Surface Finishes | HRAP, No. 1, No. 4, Pickled, Polished |

| Standards | ASTM A276, ASME SA276, EN 10088, DIN 1.4550 |

Types of SS 347 Stainless Steel Angles

Chemical Composition of SS 347 Stainless Steel Angles

| Element | % Composition |

|---|---|

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 2.00 max |

| Silicon (Si) | 1.00 max |

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 9.0 – 13.0 |

| Titanium (Ti) | ≥5× C (min) |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.030 max |

Mechanical Properties of SS 347 Stainless Steel Angles

| Property | Value |

|---|---|

| Tensile Strength | 515 – 690 MPa |

| Yield Strength | 205 MPa min |

| Elongation | 40% min |

| Hardness | ≤ 90 HRB |

| Service Temperature | Up to 900°C (1650°F) |

Applications of SS 347 Stainless Steel Angles

SS 347 angles are ideal for fabricated, welded, and heat-exposed structures, including:

Construction & Infrastructure

Automotive & Transportation

Marine & Offshore

Aerospace & Defence

Oil & Gas Industry

Manufacturing & Industrial Machinery

Why Choose Precision Alloy?

- ISO 9001:2015 Certified Manufacturer

- Wide Range of Stainless Steel Bar Shapes & Sizes in Stock

- Surface Finish Options for Decorative or Industrial Use

- Customized Machining & Fast Lead Times

- Global Delivery with Competitive Pricing

People Also Search For

- SS 347 Stainless Steel Angles for High-Temperature Service

- ASTM A276 SS 347 Equal & Unequal Angle Bar

- SS 347 vs SS 321 – Which Angle Grade is Better?

- Weld-Decaying Resistant SS 347 Angles

- SS 347 Angle Bars for Heat Exchangers & Boilers

- Buy SS 347 Angles with Titanium Stabilization

Frequently Asked Questions

What makes SS 347 suitable for welding?

SS 347 contains titanium, which stabilizes the structure against carbide precipitation during welding, preventing weld decay.

Can SS 347 be used at high temperatures?

Yes, it is designed for applications up to 900°C and resists oxidation and intergranular corrosion.

Are mirror or polished finishes available for SS 347 angles?

Yes. We provide No. 4 brushed, polished, and custom surface finishes based on application needs.

What’s the difference between SS 321 and SS 347?

Both are stabilized grades. SS 321 uses titanium, while SS 347 uses niobium/columbium, with SS 347 offering better creep strength at high temperatures.

Do you offer documentation for export compliance?

Absolutely. All shipments include MTCs, origin certificates, third-party inspection reports, and packaging as per international norms.